Continuous Training: The Strategic Answer to the Manufacturing Skills Gap and Talent Retention

Dec 18, 2025

Last updated on Dec 18, 2025

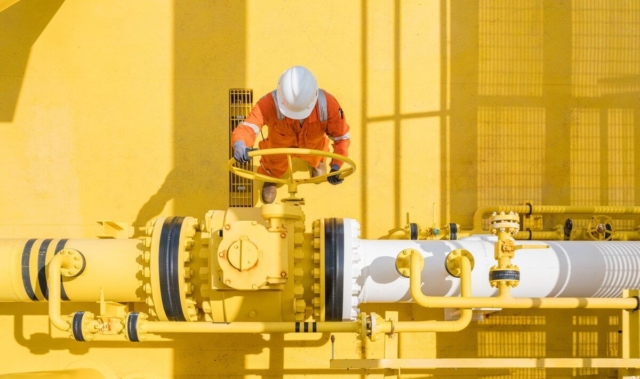

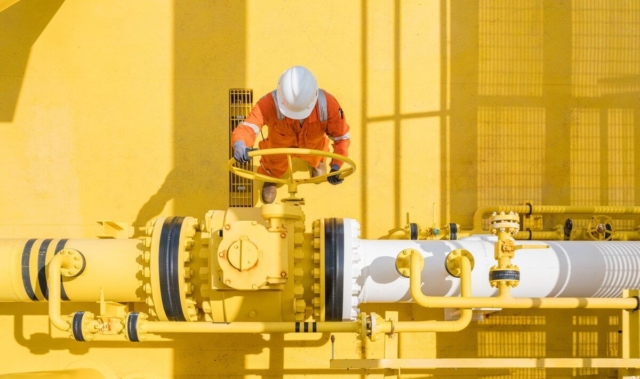

Production lines stand ready, equipment hums at capacity, yet output targets remain chronically missed. The bottleneck isn't machinery or materials—it's the growing number of positions that remain vacant quarter after quarter. For operations leaders, this isn't merely a recruiting challenge—it's a structural threat to industrial viability in an economy where talent scarcity has become the binding constraint on growth.

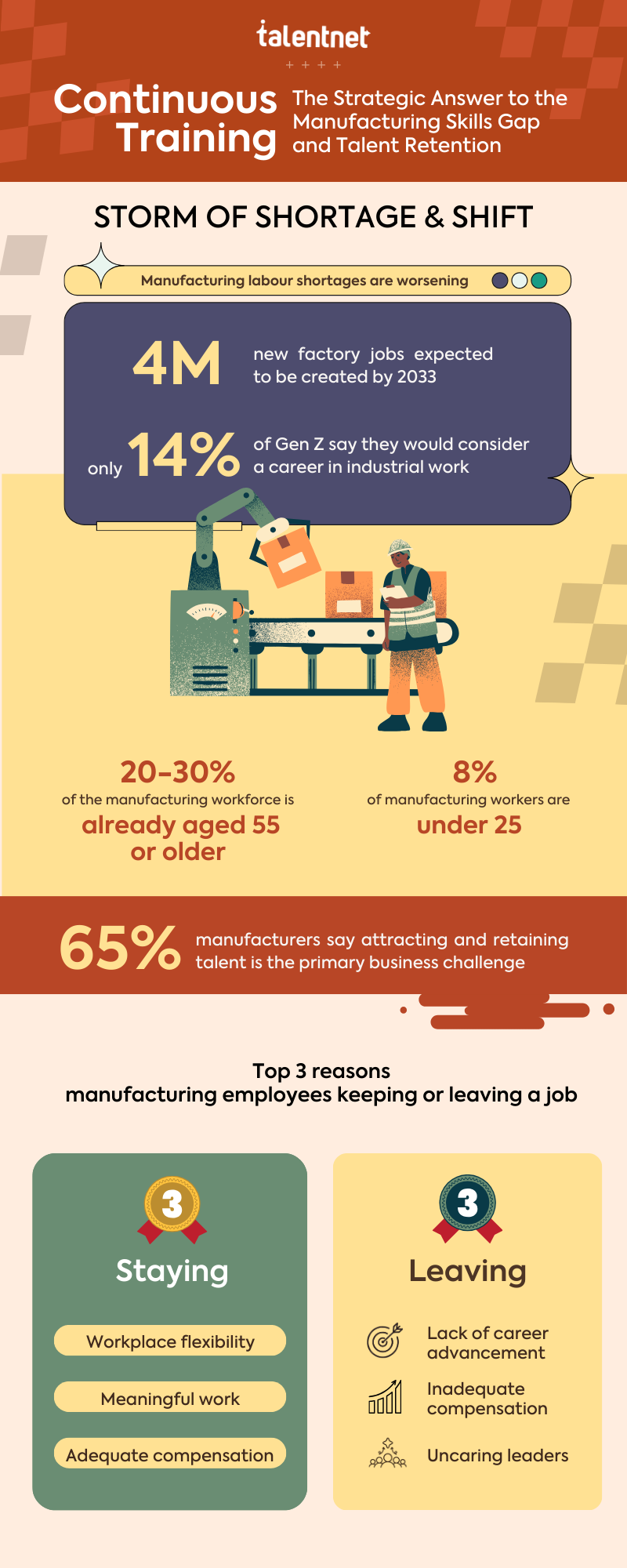

The manufacturing workforce stands at an inflection point where demographic inevitability collides with generational transformation. While 4 million new factory jobs are projected through 2033, the pipeline of workers willing to fill them has collapsed to dangerously low levels. The traditional response—raising wages and expanding recruiting budgets—has proven insufficient as incoming workers evaluate opportunities through fundamentally different criteria. The sustainable path forward requires recognizing that continuous training is no longer a support function but rather the central mechanism for building workforce resilience, bridging knowledge gaps, and creating the career architecture that modern talent demands.

Thank you for your interest in our services.

Kindly check your mailbox to get the document.

The demographic collision reshaping industrial talent

The manufacturing skills crisis manifests through three converging forces that collectively threaten operational continuity.

The retirement cliff and knowledge evaporation

With 20-30% of the workforce already aged 55 or older, the “Silver Tsunami” of retirements represents more than simple headcount reduction. When a maintenance technician with three decades of experience retires, thousands of hours of troubleshooting expertise disappear—the ability to diagnose equipment issues by sound, anticipate quality problems before they manifest, and optimize processes through accumulated pattern recognition. This tacit knowledge exists nowhere in documented form.

The timing proves particularly dangerous because only 8% of manufacturing workers are under 25, creating a demographic valley where insufficient numbers of early-career workers exist to absorb knowledge from retiring veterans. The traditional model presumed gradual knowledge transfer through extended overlap periods where experienced workers mentored successors. That transition window has collapsed.

The generational interest gap

Despite manufacturers’ efforts to modernize employer branding, only 14% of Gen Z workers consider industrial careers appealing. This “interest gap” proves more structurally damaging than numerical shortages because it reflects fundamental misalignment between what the industry offers and what younger workers value.

Factory environments optimized for decades around machine efficiency rather than human experience present rigid schedules, limited autonomy, and unclear advancement pathways—precisely the conditions that repel Gen Z employees.

The result creates a vicious cycle: low Gen Z interest means manufacturers struggle to fill entry-level positions, leading to increased workload and stress on remaining workers, which further degrades the employee experience and reinforces negative perceptions of manufacturing careers. Attracting next-generation workers to manufacturing requires fundamentally rethinking the employee value proposition.

Accelerating skill obsolescence

Technology advancement has compressed skill lifecycle dramatically. Capabilities considered cutting-edge five years ago—basic programmable logic controller operation, manual quality inspection, traditional preventive maintenance—have become insufficient as facilities deploy predictive analytics, collaborative robotics, and real-time optimization algorithms.

The World Economic Forum projects that 40% of core manufacturing skills will change by 2030, creating a double burden where companies must simultaneously onboard new workers while reskilling existing employees for increasingly digital operational environments.

Thank you for your interest in our services.

Kindly check your mailbox to get the document.

Why compensation alone cannot solve retention?

Manufacturing leaders consistently misdiagnose retention challenges as compensation problems, leading to wage increase cycles that temporarily reduce turnover without addressing root causes.

This motivation landscape fundamentally differs from older generations where compensation ranked as the dominant consideration. When 65% of manufacturers identify attracting and retaining talent as their primary business challenge, yet workers cite “lack of career advancement” as the number-one reason for leaving, a strategic disconnect becomes apparent.

The traditional manufacturing career architecture—presuming workers would accept years of static roles in exchange for employment stability and incremental wage growth—has become obsolete. Today’s workers enter jobs already mapping trajectories toward skills acquisition, role diversity, and expanded responsibility. Understanding this modern workforce mindset in manufacturing is essential for developing effective retention strategies.

Gen Z represents the only generational cohort to rank “meaningful work” as a top-three factor for taking, keeping, or quitting a job. In manufacturing contexts, this translates to understanding how specific tasks connect to broader production outcomes, customer impact, and organizational purpose. When a quality inspector understands how their work prevents field failures that could injure end users, or when an operator recognizes how efficiency improvements protect employment by maintaining cost competitiveness, the abstract concept of “meaningful work” becomes concrete. This cultural dimension is central to the HR trends reshaping the manufacturing industry.

The strategic case for training as core investment

When manufacturing leaders resist significant training investments, they cite cost concerns and productivity disruption during learning periods. However, this calculation ignores far larger costs already embedded in high-turnover operations and the opportunity costs of underutilized technology investments.

The economics of building versus buying talent

The financial comparison between external hiring and internal development proves compelling:

- New hiring: 1.5-2x annual salary when accounting for recruiting, onboarding, and ramp-up productivity losses

- Retraining existing workers: 60-90% cheaper by leveraging established cultural fit and organizational knowledge

An operator who already understands facility-specific equipment, safety protocols, and team dynamics can typically acquire new technical capabilities in one-third the time required for external hires. Organizations seeking to optimize this approach should consider strategic HR consulting services to develop integrated talent development frameworks.

The technology adoption gap reveals the real barrier

The gap between technology aspiration and realization illustrates the criticality of workforce capability. While 81% of manufacturing leaders view AI and automation as critical to competitiveness, only 14% of businesses have applied these technologies effectively. The primary barrier isn’t technological maturity or capital availability—it’s workforce capability.

Companies have invested heavily in IoT sensors, predictive analytics platforms, and automated systems only to discover that intended benefits remain unrealized because frontline workers lack skills to interpret data, act on system recommendations, or optimize algorithm performance. This capability deficit directly impacts productivity improvements in manufacturing operations.

Additionally, 64% of employers identify skill gaps as a major barrier over the 2025-2030 period. In this context, training investments function as technology enablers—the mechanism through which digital transformation actually delivers promised value.

Executing continuous training: From concept to operational system

Effective continuous training in manufacturing requires moving beyond traditional classroom models toward integrated learning systems that combine technology-enabled delivery, personalized pathways, and operational embedding.

Step 1: Define future skills

The foundation begins with mapping “hybrid” skill sets that combine technical proficiency, digital fluency, and human-centric capabilities. Traditional training focused narrowly on equipment operation or process execution. The modern framework recognizes that frontline workers increasingly need to interpret data visualizations, collaborate with AI copilots for problem-solving, and exercise judgment in ambiguous situations.

Creating detailed skills inventories enables personalized learning recommendations, identifies systemic gaps across the organization, and provides objective frameworks for advancement decisions. Understanding essential skills for manufacturing jobs helps organizations target training investments where they’ll generate maximum impact.

Step 2: Leverage technology for delivery

Technology transformation of learning delivery addresses multiple constraints simultaneously:

- Learning platforms that convert standard operating procedures into interactive courses, provide multi-language support for diverse workforces, and enable asynchronous access to accommodate shift work schedules

- Digital hubs positioned on shop floors that eliminate the productivity loss of pulling workers off-line for extended classroom sessions

- AI copilots that provide just-in-time guidance at the moment of need—an operator encountering an unfamiliar error code can instantly access resolution procedures

- VR/AR Dojos that enable safe, repeatable practice of high-risk procedures and complex equipment operations, building competency without material waste or safety concerns

Step 3: Design the learning system with three core principles

Personalized: AI-driven pathways based on individual roles and career aspirations create learning experiences tailored to current capabilities and future goals, making the abstract concept of “career development” tangible and actionable.

Experiential: Immersive learning via VR/AR Dojos and structured on-the-job practice ensures skills transfer to actual production environments rather than remaining theoretical knowledge.

Outcome-focused: Programs explicitly tied to KPIs like mean time to repair, downtime reduction, and promotion rates demonstrate business impact while providing workers concrete evidence of capability development.

When workers can visualize their current position on a skills matrix and understand exactly which capabilities they need to develop for promotion or role transition, training transforms from compliance requirement into career investment that drives retention. This integration of culture change and manufacturing engagement creates sustainable competitive advantage.

Companies that execute this transformation effectively will gain profound competitive advantages—operational resilience through reduced dependence on external talent markets, enhanced productivity through digitally capable workforces, and superior innovation capacity as employees gain skills to optimize increasingly sophisticated production systems. Organizations seeking comprehensive support in this transformation can leverage Talentnet’s HR outsourcing services to accelerate capability building while maintaining operational focus. In an era where capability determines competitiveness, training is no longer optional—it’s the strategic imperative that separates industrial leaders from those struggling to maintain operational viability.

Thank you for your interest in our services.

Kindly check your mailbox to get the document.

Solve your HR problems!

6th Floor, Star Building, 33 Mac Dinh Chi, Saigon Ward, Ho Chi Minh city, Vietnam